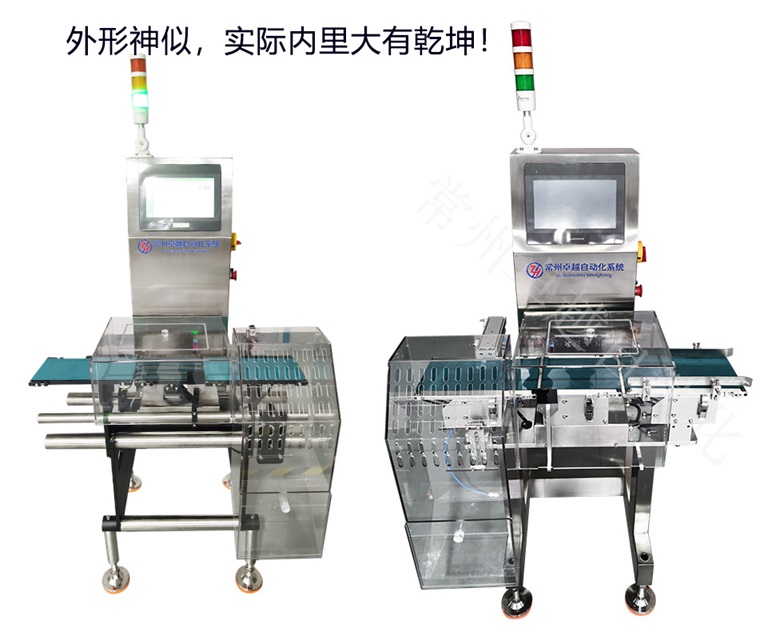

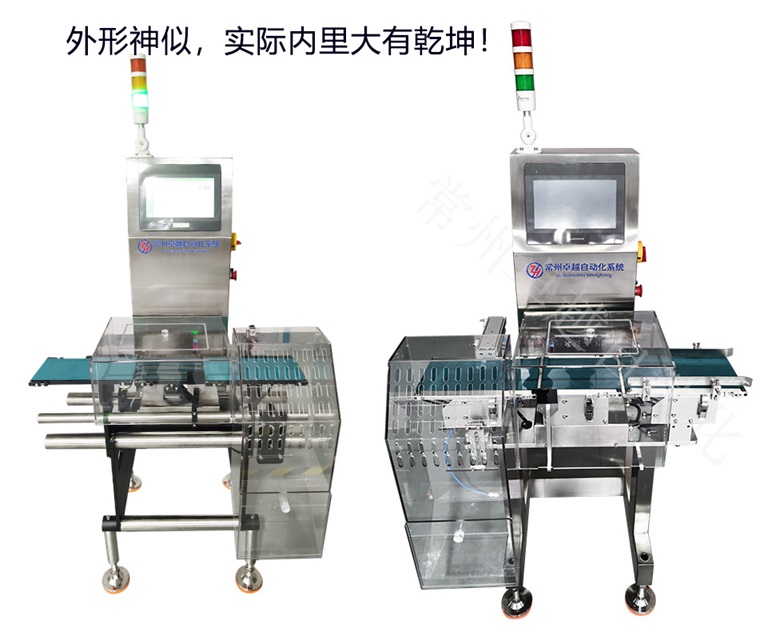

Why do seemingly identical checkweighers have such different prices?

Automatic

checkweighers are widely used in many industries such as food, beverages, pharmaceuticals, and chemicals. Different industries have different product types, and different industries have different requirements for weighing accuracy. Therefore, the price will be different due to different configurations and customized prices.

The main reason for the price difference of

checkweighers is the difference in accuracy, stability, durability, etc.

High-precision checkweighers can provide more accurate weight measurement and reduce errors. They are suitable for strict occasions, such as pharmaceuticals and food industries.

Checkweighers with good stability can maintain measurement accuracy in various environments and are not affected by temperature and humidity.

Checkweighers with strong durability can withstand more frequent use and reduce maintenance and replacement costs.

These factors jointly determine the price of checkweighers. Therefore, the prices of seemingly identical checkweighers vary a lot.

Most domestic factories are small and medium-sized automated production lines, and the various configurations of automatic checkweighers are sufficient to meet the needs of existing small and medium-sized manufacturers. Of course, the price of automatic checkweighers is affected by various factors. The weight of the measured product is different, and the requirements for accuracy are also different. The corresponding automation technology requirements are also high. Overall, they can meet the requirements.

For ordinary food, beverage, and logistics manufacturers, an automatic checkweigher with a price of 30,000 to 50,000 yuan is enough to meet the manufacturer's weighing specification requirements.

For industries that require precision, such as those that require higher weighing accuracy and resistance to harsh environments, ordinary checkweighers cannot meet the needs of this industry. For industries such as chemical powders that have high environmental requirements, automatic checkweighers must be corrosion-resistant, vibration-resistant, and have higher precision requirements.

In general, the purchase should still depend on the actual needs of the manufacturer. At the same time, it is also necessary to look at the speed of the automatic checkweigher and the overall material structure, and understand whether the basic functions are complete.

A good automatic checkweigher can save labor costs for manufacturers, efficiently replace manual sorting, and can count the weight of each bag and the number of bags loaded online when the production line is running, ensuring that data is uploaded in real time and can detect whether the product weight is qualified online, reducing labor costs, and making installation and adjustment more convenient for later maintenance and safer to use.