Weighing System Hardware Analysis of Checkweigher

The checkweigher is a high-precision checkweigher for packaging production lines. It can be integrated with various packaging production lines and conveying systems. It is mainly used to detect whether the product weight is qualified online and archive it for later traceability analysis.

The hardware system of the dynamic checkweigher is the physical basis of the entire measurement and control system. According to the requirements of the measurement and control system functions, the hardware system is built and optimized. The hardware of the

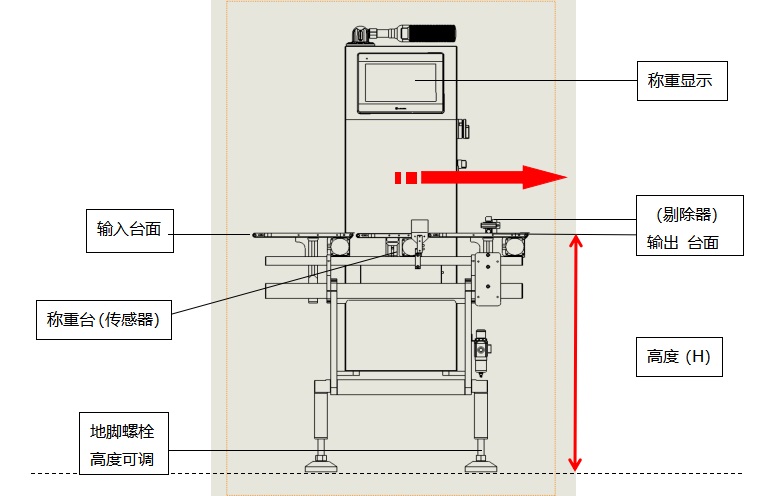

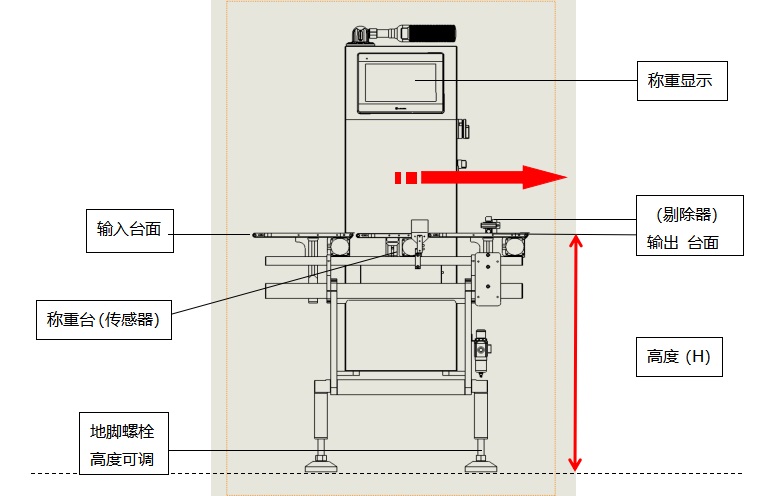

Online Checkweigher system mainly includes the following parts: computer, signal detection part, signal conditioning circuit, data acquisition card part, control part and actuator.

1. Computer: the center of data acquisition, data management and control decision-making of the entire measurement and control system.

2. Signal conditioning circuit: amplify, excite, linearize, isolate and filter the signal.

3. Signal detection part: mainly refers to pressure sensors, which are responsible for real-time conversion of dynamic weighing quality signals and transmit the converted electrical signals to the data acquisition board.

4. Weighing display controller: The computer processes according to the control setting parameters, obtains the control results through a certain control algorithm, and transmits the control results to the actuator. The weighing display control instrument can display the gross weight, net weight, the last weighing value, and the difference between the last weighing value and the set nominal value. It can also display the total number of weighed pieces, the number of underweight pieces, the number of overweight pieces, and the number of qualified pieces. The checkweigher display controller can also transmit a variety of statistical information, and can connect useful information to the management computer through the communication interface or print out reports through the printer.

5. Data acquisition card part: including data acquisition card and its supporting equipment, the collected data is converted by A/D and transmitted to the computer for further analysis and processing; then the control results output by the computer are converted by D/A and output to the control part.

6. Execution rejection device: According to the packaging form and characteristics of the inspected items, the rejection device can be divided into multiple modes such as pushing out, tipping down, and handling. The actuator performs corresponding actions according to the control results to timely reject the packaging products that do not meet the quality standards. (This item can be adjusted according to the characteristics of the product line)